With the development and perfection of the motherlands chemical system, the market for chemical additives is slowly becoming larger, in terms of silicone masterbatch, technology and process are extremely transparent, many large companies can make the products of small companies, the possibility of some differences, but the appearance seems to be the same, because of this reason, many manufacturers in the choice of silicone masterbatch, sometimes choose to substandard products, or even inferior products, resulting in a large number of problems with the late end product, a great loss!

Based on the above 3 issues, how do we identify high quality silicone masterbatch? First of all, we must know the basic information of the suppliers products, including silicone is not the use of automated twin-screw extrusion process, which is very critical, which can directly control the stability of the product later, this process is very necessary: then look at the suppliers silicone masterbatch whether through the EU SGS environmental certification, PAHS, ROHS, REACH, NP, phthalates and other environmental certification. This is a quality control of the product; next is the sample, test a silicone masterbatch whether they can achieve their required performance, these 3 points to control well, I believe that the silicone masterbatch has a comprehensive control. And the most important point, whether the supplier is bold enough to promise: whether the future supply and the samples tested can guarantee the same, whether they dare to seal the sample preservation, which is a very good protection for themselves, but also very test the suppliers confidence in the quality and stability of their silicone masterbatch!

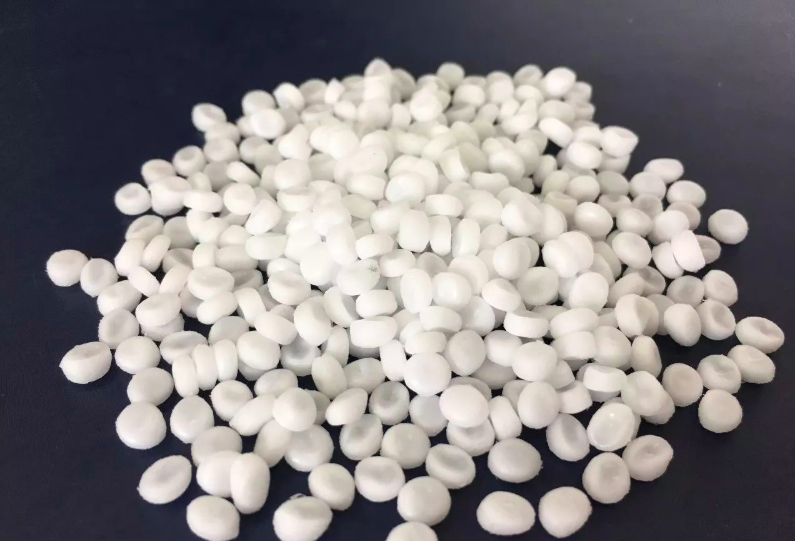

Xiamen Xiangsilicon New Material Co., Ltd. is a high-tech enterprise specializing in the research and development, production, sales and service of organosilicon product derivatives. Focusing on the application of silicones in the field of plastics, the company has a number of senior experts in the field of silicones to provide personalized solutions and potential applications for customers with different needs. With the help of our R&D staff, we have formed a strong R&D team to provide consumers with more cost-effective and environmentally friendly products to save material costs and protect the environment. We have successfully developed ultra-high molecular weight silicone masterbatches and ultra-high content silicone masterbatches, which have been applied to hundreds of thermoplastic elastomers, engineering plastics, automotive interior parts, wires and cables, and high-grade shoe materials, etc., and have been well received by the market! Based on the above research and development, we have invented several patents and have achieved successful applications.

Silicone products have excellent heat resistance and insulation properties, will greatly improve the depth of the use of materials value, the introduction of fully automated production control system, the product is widely used in: modified engineering plastics, automotive parts, wire and cable, shoe manufacturing, pipe making, rubber and plastic, film and other areas of industry has been successfully used widely, and even become the key leading element of innovation in certain applications. The quality is stable and reliable, and the quality is highly praised by our customers and has gained a good reputation; we have also passed various environmental certifications such as EU SGS, PAHS, ROHS, REACH, NP, phthalate, etc.